For those of you running your own e-commerce business, the term “3PL” or third-party logistics is probably old news. One big perk of working with a 3PL is that they can handle all your warehousing needs. If you’ve been managing your warehousing operations solo for a while, you might already be nodding in agreement about how much easier it would be to let a 3PL handle it.

That said, as with any business decision, there are still a couple of things to be mindful of when deciding to delegate your warehousing and order fulfilment tasks to an external party. After all, the choice to outsource these components of your business will directly impact your customer service. But don’t worry, we’ll dig into that real soon.

Going for third-party warehousing is often the smartest money move for most e-commerce businesses. These 3PLs have their own storage spaces, equipment, and skilled teams that can handle orders, even during peak times.

The great thing about 3PLs is that they use what’s called “economies of scale” – where the cost per unit of production or operation decreases as the scale of output or activity increases. In simpler terms, this means they can provide services at a lower cost compared to individual businesses attempting to manage the same tasks independently.

By sharing resources with 3PLs and not needing to own warehouses or assets yourself, you can significantly lower your business’s operating costs.

Okay, now let’s get back to that checklist.

When you’re scouting for a 3PL partner, you’re in search of reliability. You want the ones who’ve been there, done that, and aced it – especially when it comes to inventory management, efficient transportation, and compliance with regulations.

Imagine outsourcing your supply chain tasks as a step-by-step journey. First, you plan and test, then you put the plan into action. At each stage, both your third-party logistics provider and your company learn. Some things might be out of your logistics partner’s control, but they affect how things work. So, managing them alongside your outsourcing project is important.

A good 3PL provider will come equipped with a warehouse management system (WMS) and other tech tools to make your operations smoother and more efficient. But before you make the big shift, make sure to thoroughly test your own IT systems. Tech glitches have a knack for appearing inconspicuously, and you want your systems to work seamlessly with your new partner’s.

When you’re in the planning stage, you share your data with the logistics service provider to get a price estimate. But the thing is, sometimes data like units of measure, weight, dimensions, and units sold might not hold up when put into action.

The data you use for the estimate usually gets taken from different systems and tweaked a bit. And this can lead to IT glitches and more manual work later on. So, keep an eye on data quality and make sure to get an accurate quote from your logistics provider.

Over time, your supply chain team has gained valuable insights that might not be written down anywhere. Ignoring certain details like how customers like their goods stacked or specific packaging requests can cause real headaches when you’re shifting to outsourcing.

So, don’t disregard those unofficial insights – gather knowledge from all corners of your supply chain team to make the transition as smooth as possible.

Running your logistics show with a 3PL is a different tune compared to running your own warehouse. You’ll need to consider things like negotiating service level agreements, measuring performance based on solid data, and steering based on predefined KPIs. It’s a shift from the typical management style you’d use for your own warehouse operations.

If you want to partner with a logistics provider that knows exactly what they’re doing when it comes to warehousing and cares about protecting your assets and growing your business, you’ve found it in Airpool.

When you team up with Airpool, your goods will be efficiently consolidated at our warehouse in Yiwu, China, and then it will be dispatched as a single package to your final destination in SA. That means you can shop from various suppliers without breaking the bank, all while partnering with a company that’s all about fuelling your small business growth and guiding you on the journey.

Even if our services aren’t your cup of tea, we’re here to point you in the right direction with the resources you need. Get in touch with us to learn more about what we can do for your business.

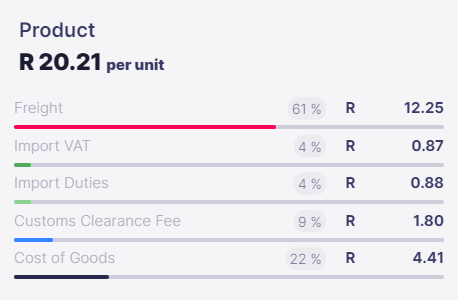

Landed cost is the sum of all expenses associated with importing your goods from China to South Africa. This includes the cost of the goods paid to your supplier, the shipping costs, clearance costs and the import taxes & duties.

It is represented on a per unit cost and helps you with:

Note: This is not what you are paying to Airpool but rather what you are paying to all the suppliers and relevant parties: Airpool, the Manufacturer of the goods and the Import Taxes (VAT & Duties)