With the introduction of automation, big data, and asset sharing to the industry, the future of the supply chain and logistics might appear uncertain. However, these advancements could spell out positive changes for all parties.

Welcome to the future, folks! We are firmly entered into the Fourth Industrial Revolution, which means that fundamental shifts are happening in industries all around us at a rapid and universal rate. Technological advancements have changed the way we do almost anything, from ordering a cab to buying groceries.

So, what does that mean for the supply chain and logistics industry? As the industrial landscape transforms before our eyes, inevitable anxieties arise about the place of people in an increasingly automated supply chain. In a world of robots, where are human beings going?

The short answer is: nowhere.

Like we said: no.

But, to assuage any anxieties, let’s get into the logic of that answer. As this Forbes article articulates, advancements like AI, big data, and increased automation are inevitable changes that we can expect to take effect in the supply chain.

However, “While there is no question that the current supply chain is being disrupted, it’s clear supply chain management is not dead or dying. It’s evolving, just as it has been since its inception.”

The introduction of new technologies is not going to replace people, it’s just going to replace tasks. To clarify, although some jobs are going to be made more efficient by the use of technology like drones and self-driving vehicles, human talent is always going to be the number one priority of supply chain management.

People who occupy jobs like inventory management are not going to be made redundant. Logistics companies are simply going to have to reskill their employees to make these processes viable. So, while drones might take over the task of selecting and sorting huge stores of inventory, the human touch is irreplaceable when it comes to interpreting data patterns and facilitating logistics processes.

If anything, automation invites the possibility of not just reskilling, but upskilling human employees. People are not being pushed out, we are being pushed up into more skilled, managerial positions. Changes to the supply chain are inevitable, but the redundancy of human talent is not.

According to this article by McKinsey, three major factors are going to profoundly transform the way that logistics operates in the near future. They are:

1. Automation

2. Data and analytics

3. Asset sharing

We’ll explain the individual effect of each of these factors under their own headings.

Perhaps the biggest change that is coming (and, in some instances, has already come) to the world of logistics is fully-automated processes. The McKinsey article focuses particularly on the effects of autonomous trucks, or ATs. The implementation of self-driving trucks would, according to their research, drive (ha!) operation costs down by 45%. That’s a huge fraction. In more granular terms, full autonomy would save the US for-hire trucking industry somewhere between $85 billion and $125 billion.

Trucking isn’t the only facet of logistics that is facing automation, though. Given the nature of our industry, shipping and logistics could benefit from automation at every step. McKinsey predicts that comprehensive automation would expand companies’ abilities to take on heavier cargo, streamline picking and packing operations, and take on peak demand with more flexibility.

If the supply chain was comprehensively automated with collaborative robots, an advanced sorting system, and indoor drones that sorted through inventory with broadband efficiency, the consulting firm reckons that logistics costs could fall by 40%.

As new technologies and improved systems make quantifying big data more efficient, it’s becoming easier and easier to forecast demand and supply. This equips companies with the knowledge they need to optimise routes and edit inventory.

This kind of knowledge can essentially be understood as visibility. The better we get at curating insightful information about routes and inventory patterns, the better we can communicate to end-buyers about their shipments. Absolute digital transparency that is easy to access is where Airpool excels. We have eyes on your package from the second they enter our Wihu hub to the moment they land on your doorstep.

In the long run, the total visibility we gain from the effective application of data and analytics will reduce administrative burdens, minimise risks, and reduce operational costs. Good news all around!

If you’ve ever used Uber or Airbnb, then you’ll intuitively understand how asset sharing works. If we could outsource the logistics of tracking assets like trucks or warehouse space to an advanced, online system, then the B2B sphere can expect to unlock unused capacity in capital-intensive assets.

This is also where consolidation comes in. Consolidating goods with a service like Airpool is like shipping your goods using rideshare technology. Because the cost of shipping is calculated using the metrics of bulk, consolidation is an extremely attractive and cost-effective option for shippers who are looking to optimise the supply chain between China and South Africa.

The supply chain and the world of logistics are moving rapidly into the future – don’t get left behind! With services like Airpool in your corner, there is no need to panic. We’ll keep your business (and your time-sensitive shipments) up to speed. The future is here. Beam us up, Scotty!

How millennials entrepreneurs are changing the face of eCommerce [UPDATED 2022]

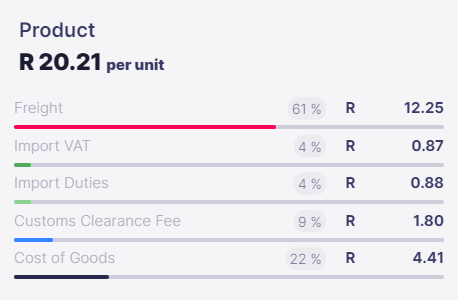

Landed cost is the sum of all expenses associated with importing your goods from China to South Africa. This includes the cost of the goods paid to your supplier, the shipping costs, clearance costs and the import taxes & duties.

It is represented on a per unit cost and helps you with:

Note: This is not what you are paying to Airpool but rather what you are paying to all the suppliers and relevant parties: Airpool, the Manufacturer of the goods and the Import Taxes (VAT & Duties)